Turned, Ground, and Polished (TGP) stainless steel has emerged as a cornerstone material in today’s manufacturing landscape. Known for its precision, durability, and high-quality surface finish, TGP stainless steel meets the rigorous demands of advanced engineering applications. As industries continue to evolve, the importance of sourcing reliable TGP materials from trusted suppliers, such as Specialty Steel stainless steel distributor, cannot be overstated. With the steady pace of technological innovation, manufacturers are increasingly turning to TGP stainless steel for its combination of mechanical strength and dimensional accuracy.

This specialty stainless steel undergoes processes that improve its structure and appearance, making it popular in industries needing durability, low maintenance, and high performance. Automotive, aerospace, robotics, and machinery industries often choose TGP stainless steel for key components due to its consistent quality and superior engineering. It enhances product longevity and simplifies manufacturing by reducing secondary operations. Its surface finish and precise tolerances allow engineers to push technological limits, ensuring reliable high-performance results. With ongoing innovation, TGP stainless steel will continue to support future industrial advancements. Its reliability and resistance to wear and corrosion ease the entire product lifecycle from production to application.

Understanding TGP Stainless Steel

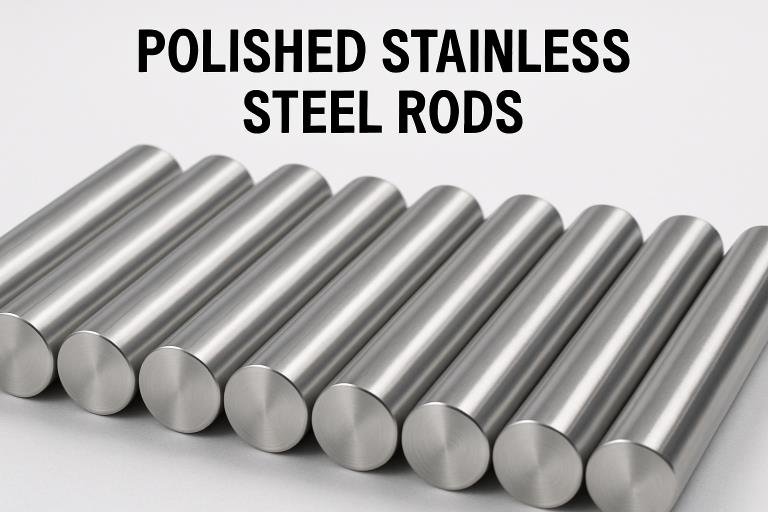

TGP stainless steel is made by refining standard steel bars through turning, grinding, and polishing, resulting in better shape accuracy and a smooth, reflective surface. This process removes natural imperfections found in original bars, creating a uniform material with reliable properties. The final product is suitable for high-tolerance components needing reliability and performance. Thanks to these improvements, TGP stainless steel addresses shortcomings of standard bars in aesthetics and engineering. Its increased strength and consistency suit demanding applications.

Manufacturing Process of TGP Stainless Steel

The production of TGP stainless steel involves a systematic sequence of steps designed to enhance its quality and precision. Initially, rough bars undergo turning to eliminate surface irregularities and ensure consistent diameters. Following this, the bars are subjected to grinding with abrasive wheels to improve roundness, straightness, and overall surface quality. The final polishing step gives the steel a mirror-like finish, enhancing smoothness, minimizing friction, and maximizing corrosion resistance. This meticulous process results in steel that adheres to stringent tolerances, making it suitable for assembly into complex systems. Notably, the manufacturing techniques for TGP stainless steel are continuously advancing, facilitating faster production and heightened accuracy.

Key Benefits of TGP Stainless Steel

The precision fit of TGP bars ensures they meet controlled dimensional tolerances, allowing for seamless assembly integration and reducing the need for costly redesigns and post-processing efforts. The Superior Surface Quality, achieved through advanced polishing methods, minimizes micro-cracking and maintains a smooth finish over prolonged use. Additionally, the process enhances the strength of the steel by eliminating defects, which significantly improves its integrity, making it suitable for high-load applications with a lower risk of sudden failure. Furthermore, the Corrosion Resistance provided by the high-quality finish prevents rust formation, thereby extending the service life of the material even in aggressive environments.

Applications in Various Industries

The versatility of TGP stainless steel is highlighted through its diverse applications across various industries. In the automotive sector, it is crucial for components like drive shafts, transmission parts, and suspension systems to offer both safety and durability. In aerospace, TGP is utilized in turbine shafts, actuator rods, and landing gears, and is reliable under repeated stress cycles. Its role in industrial automation includes being used in precision bearings, spindles, and guide bars, which are valued for their reliability and minimal maintenance requirements. In robotics, TGP stainless steel contributes to the smooth movement of robotic joints and axles, enhancing operational efficiency. As industries increasingly prioritize accuracy and reliability, the application of TGP stainless steel is expected to expand.

Enhancing Performance in High-Speed Applications

Many high-speed and precision applications rely on TGP (Turned, Ground, and Polished) stainless steel for efficiency and performance. The precise manufacturing of TGP bars significantly reduces vibrations, which helps prevent early equipment failures. Polished surfaces reduce friction, resulting in lower heat generation, enhanced energy efficiency, and extended equipment lifespan. Additionally, TGP stainless steel boasts high fatigue resistance, ensuring reliability under constant, repetitive stress and motion. Consequently, the proper utilization of TGP stainless steel is crucial for achieving smoother and more dependable high-speed operations.

Importance of Surface Finish in TGP Stainless Steel

Surface finish plays a critical role in TGP stainless steel, impacting various factors beyond its aesthetic appeal. Firstly, the attractive mirror finish is prized in architectural and product design for its contemporary appearance. Secondly, the smooth surface contributes to hygienic benefits by allowing for easier cleaning, making it suitable for use in sanitary settings such as hospitals and food processing facilities. Lastly, a finer and more uniform surface enhances corrosion resistance, extending the durability and longevity of the material in various applications.

Advancements in TGP Stainless Steel Manufacturing

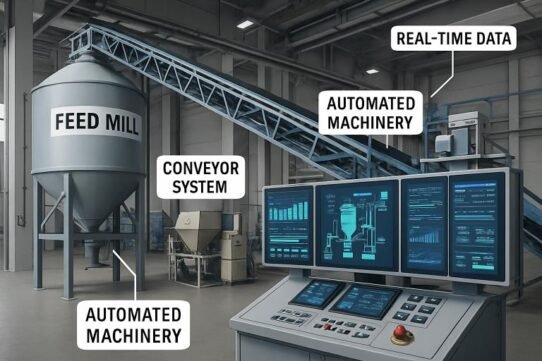

The industry has experienced significant technological advancements in TGP stainless steel, highlighted by several key developments. Automation has enabled the use of automated grinding and polishing techniques, resulting in consistent, high-quality finishes within reduced timeframes. Furthermore, high-speed turning and grinding processes facilitate rapid and precise material removal, supporting mass production without compromising accuracy. The implementation of centerless grinding enhances uniformity and minimizes manual handling, thereby increasing overall efficiency. Collectively, these innovations have made TGP stainless steel products more accessible and affordable, promoting widespread adoption across various sectors.

Conclusion

TGP stainless steel remains an indispensable component in engineering and manufacturing due to its unique combination of mechanical, structural, and aesthetic advantages. Its ability to provide superior precision, outstanding durability, and high-quality surface finishes ensures its presence in the most demanding and innovative applications. As the industry adopts even more advanced production methods, TGP stainless steel stands out as the material of choice for those seeking reliability and excellence across a wide range of manufacturing environments.