Key Takeaways

- Adoption of automation and AI leads to significant gains in efficiency and throughput.

- Energy-saving technologies and resource management practices reduce costs and improve sustainability.

- Advanced, real-time monitoring systems strengthen safety and transparency.

- New ingredient processing and modular mill designs offer greater adaptability and green options.

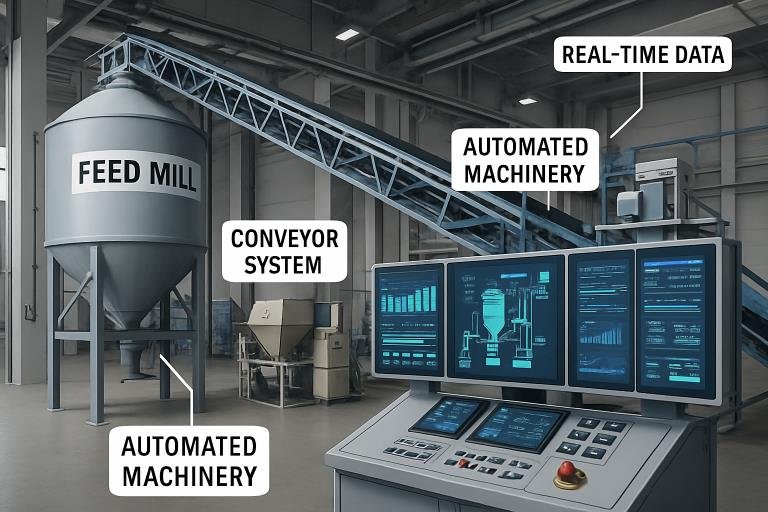

Feed mill operations are undergoing rapid transformation as the agricultural sector embraces technological advancements that enhance efficiency, sustainability, and product quality. The integration of automation, artificial intelligence, and new processing methods is redefining the possibilities for animal nutrition and business productivity. Whether upgrading an existing facility or planning a new plant, choosing experienced suppliers such as Cruco Mill & Industrial Supply feed mill suppliers can ensure access to the latest solutions, keeping your operation at the forefront of these changes.

Across critical areas such as energy use, ingredient sourcing, and production monitoring, innovative approaches are yielding substantial improvements. For today’s feed mill managers and agricultural professionals, understanding these advancements is key to future-proofing business operations and maintaining competitive advantage in a dynamic global market.

Implementing these solutions not only ensures regulatory compliance but also opens up new possibilities for innovation within the feed sector. Industry leaders are investing in long-term strategies to balance profitability with environmental responsibility.

Automation and AI Integration

Automation and AI technologies are rapidly becoming cornerstones of efficient feed mill management. Automated batching and mixing systems use sensors and controls to achieve consistent ingredient blending, ensuring every feed batch meets nutritional specifications. AI-powered predictive maintenance tools detect equipment wear and forecast failures, reducing costly unplanned downtime. Integrated AI scheduling platforms adjust production priorities in real time, helping mills increase throughput by nearly 30% in some cases. These advancements not only streamline workflow but also allow staff to focus on high-value tasks that require human oversight.

Energy-Efficient Technologies

Rising energy costs and environmental mandates have driven feed mills to adopt energy-efficient technologies at an unprecedented rate. Upgrades such as variable-frequency drives on motors, high-efficiency compressors, and optimized conveyor systems can reduce energy consumption by as much as 20%. These systems lower carbon footprints and utility bills, while also qualifying some operations for government incentives and sustainability certifications. Investments in renewable energy sources and heat recovery from process exhaust are also on the rise. Moreover, intelligent monitoring and automation enable real-time tracking of energy consumption, uncovering additional efficiency opportunities. Over time, these strategies not only boost operational resilience but also position the mill as a sustainable and progressive operation.

Advanced Monitoring Systems

Monitoring technology has evolved from simple process controllers to sophisticated, interconnected systems leveraging the Internet of Things (IoT). IoT-enabled sensors capture everything from motor vibrations and temperature fluctuations to moisture levels and ingredient traceability. Managers receive instant alerts about deviations, empowering rapid intervention and continuous quality assurance.

According to a report, feed mills that implement real-time analytics are saving on maintenance costs and gaining detailed insights for continuous improvement. These data-driven strategies deliver return on investment by optimizing inventory, reducing emergency deliveries, and preventing costly recalls.

Innovative Ingredient Processing

The sustainability movement has fueled innovation in feed ingredient sourcing and processing. Feed mills are exploring alternative proteins, including insect larvae, single-cell proteins, and microalgae, which are often produced with fewer resources and a smaller environmental footprint. Processing technologies such as extrusion, fermentation, and enzymatic treatment enhance nutrient absorption and tailor feed products for specific animal health benefits.

This drive for sustainability aligns with global efforts to reduce carbon and water intensity in agriculture. The use of novel ingredients and tailored formulations helps producers respond to market demand for responsibly sourced feed while supporting animal nutrition.

Modular Feed Mill Designs

Flexibility is increasingly critical in feed mill design. Modular construction approaches allow facilities to scale efficiently, adapting to changing production quantities or new feed formulations without significant disruptions. Prefabricated modules reduce construction time and cost while supporting custom configurations for specific operational needs. As highlighted by large-scale projects in the U.S. and Europe, modular feed mills help operations grow organically and adjust quickly to evolving market conditions.

Water Conservation Practices

As water scarcity threatens predictive agriculture worldwide, feed mills are adopting closed-loop systems and water-reclamation technologies. Innovations like the “AquaRecycle” system can recover up to 80% of water from tempering processes and reuse it within the facility. These systems not only cut municipal water costs but also help mills comply with environmental regulations.

Strategic water management, including real-time monitoring and rainwater harvesting, further supports sustainability and aligns operations with international best practices for environmental stewardship.

Traceability and Blockchain

Blockchain technology is revolutionizing feed traceability and food safety across the supply chain. By storing immutable records of every transaction and ingredient batch, blockchain systems guarantee transparency for regulators and customers alike. Feed mills using blockchain can provide instant proof of compliance and strengthen trust with business partners and end consumers.

Major players in agri-food are already leveraging blockchain to monitor feed sources, improve export documentation, and meet rising consumer expectations on transparency.

Conclusion

Innovative solutions—from automation to green energy and traceability—are shaping the future of modern feed mill operations. By adopting these technologies and practices, feed mill managers not only achieve operational efficiency and sustainability but also ensure the production of safe, high-quality products that meet evolving industry demands.